GREEN TECHNOLOGY

Graphite : essential for the green technology

The road to the green energy revolution is paved with Graphite.

Renewable energy

Isostatic graphite is essential to silicon production used in solar panels. Because it is resistant to extreme heat it is perfect for the crucibles and moulds used to cast the silicon in solar panels, and in use it works as heat shield and thermal insulation. It is also used in the batteries that store the energy from solar and wind farms once the energy is produced.

Nuclear reactors

Nuclear graphite is any grade of graphite, usually synthetic graphite, manufactured for use as a moderator or reflector within a nuclear reactor. Graphite is an important material for the construction of both historical and modern nuclear reactors, due to its extreme purity and ability to withstand extremely high temperature.

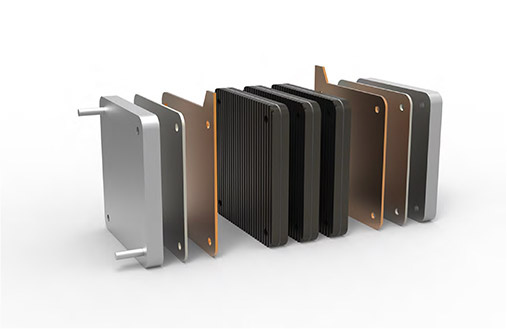

Fuel cells

Fuel cells have become a viable eco-friendly power source, and advancements in the technology continue to be made. Fuel cells have many applications already, and the potential uses will only grow as this technology is developed further. Right now, fuel cells are used to deliver electrical power in commercial, industrial, residential and remote settings. The cells may be used as a primary or backup power source.

Graphite is the leading material for the construction of bipolar plates in fuel cells. The graphite used in bipolar plates must be processed specifically for fuel cells and batteries, as other forms of graphite don’t provide all of the traits that bipolar plates need. Natural flake graphite is usually the raw graphite that’s processed for this purpose.

Lightweight construction

Lightweight design develops innovative solutions for customized

and resource-efficient lightweight constructions for mobility systems and transport infrastructure. The demand for lower energy consumption and reduced CO2 emissions means that the need for innovative lightweight solutions is high. Lighter constructions offer the possibility for an eco-friendlier mobility. In terms of transport infrastructure lighter constructions are also more resource-efficient.

Carbon fiber is composed of strands of fibers 5 to 10 microns in diameter that consist of long, tightly interlocked chains of carbon atoms in a microscopic crystalline structure. These fibers are extremely stiff, strong, and light, and are used in many processes to create high-performance building materials. Carbon fiber reinforcements come in a variety of weaves, braids, and other formats such as tow, and uni-directional. These are combined with various resins to produce carbon fiber-reinforced composites in a wide range of shapes and fiber patterns.

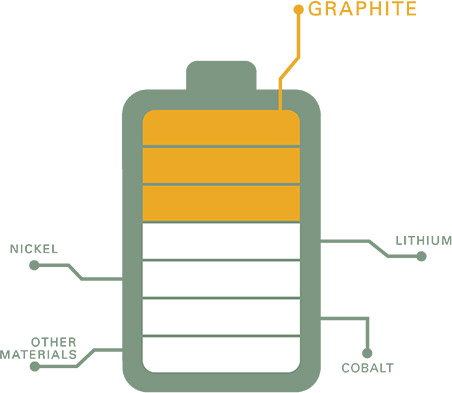

Lithium-ion batteries

The anode in Li ion batteries (LiBs”) is made out of graphite. A graphite anode is one of the things that make it a LiB and there are no substitutes. LiBs are smaller, lighter and more powerful than traditional batteries and have a flat voltage profile meaning they provide almost full power until discharged. They also have no memory effect and a very low rate of discharge when not in use. Almost all portable consumer devices such as laptops, cell phones, MP3 players and cameras use Li-ion batteries, and they are now rapidly moving into power tools and bigger devices. This has led to 20% annual growth in the LiB market.

By weight, graphite is the largest component in LiBs and they contain 10-15 times more graphite than lithium. Because of losses in the manufacturing process, it takes over 30 times as much graphite to make the batteries.

There is up to 10 kgs of graphite in the average Hybrid Electric Vehicle and up to 70 kgs in an Electric Vehicle. Because of the small size of the flake graphite market, even modest, conservative EV adoption rates will have a big effect on demand.

Almost all Li-ion battery manufacturing currently takes place in China because of the ready availability of graphite, weak environmental standards and low costs. Increasingly, secure, cost competitive and environmentally sustainable source of graphite are needed in the west.

Clean Steel

The EU Clean Steel Partnership (CSP) started in June 2021 in the Framework of Horizon Europe and creating synergy with the Research Fund for Coal and Steel (RFCS) as a public private partnership.

The Memorandum of Understanding (MoU) signed by DG RTD and DG Grow and ESTEP aims to achieve carbon neutral steel making technologies and to allow for sustainable growth in the sector.

The main document describing the Clean Steel Partnership is its Strategic Research Agenda (SRIA).